ELECTRONICS LAB PACKAGE

Develop your electronic components faster by combining multiple techniques

Accurately measure CTE of materials and test material compatibility.

Determine the potential for delamination of layered materials through measurement of the CTE of the various layers. Material compatibility can easily be determined.

Easily measure multi-layer material thicknesses and gain critical information about the properties of each layer or the entire sample.

The TMA, with the penetration probe, can easily measure the thickness of layers in a multi-layered sample and the DSC can provide information such as glass transition temperatures and heat capacity of the samples.

TGA Part 1 - Theory & Instrumentation

Monday, June 22 at 1:00 pm EDT

This lecture-based course covers all our TGA instruments, but is mainly designed around the Discovery TGA 55, 550, & 5500 instruments. The course will cover:

- Theory of operation

- Instrumentation

- Experimental parameters

- Software operation

- Calibration

- Maintenance & Troubleshooting

- Applications

Request More Information

Revolutionary New Fusion Cell™

Revolutionary new Fusion Cell™ further improves the performance on which you’ve come to rely. Better sensitivity, resolution, repeatability and industry leading baseline performance, enable detection of the weakest thermal transitions and the most accurate enthalpy and specific heat capacity.

Powerful TRIOS Software

Revolutionary new Fusion Cell™ further improves the performance on which you’ve come to rely. Better sensitivity, resolution, repeatability and industry leading baseline performance, enable detection of the weakest thermal transitions and the most accurate enthalpy and specific heat capacity.

Modulated DSC®

Revolutionary new Fusion Cell™ further improves the performance on which you’ve come to rely. Better sensitivity, resolution, repeatability and industry leading baseline performance, enable detection of the weakest thermal transitions and the most accurate enthalpy and specific heat capacity.

RCS 120 Refrigerated Cooling System

Revolutionary new Fusion Cell™ further improves the performance on which you’ve come to rely. Better sensitivity, resolution, repeatability and industry leading baseline performance, enable detection of the weakest thermal transitions and the most accurate enthalpy and specific heat capacity.

High Throughput DSC Autosampler

Revolutionary new Fusion Cell™ further improves the performance on which you’ve come to rely. Better sensitivity, resolution, repeatability and industry leading baseline performance, enable detection of the weakest thermal transitions and the most accurate enthalpy and specific heat capacity.

New Microscope Accessory

Revolutionary new Fusion Cell™ further improves the performance on which you’ve come to rely. Better sensitivity, resolution, repeatability and industry leading baseline performance, enable detection of the weakest thermal transitions and the most accurate enthalpy and specific heat capacity.

Revolutionary New Fusion Cell™

Revolutionary new Fusion Cell™ further improves the performance on which you’ve come to rely. Better sensitivity, resolution, repeatability and industry leading baseline performance, enable detection of the weakest thermal transitions and the most accurate enthalpy and specific heat capacity.

Powerful TRIOS Software

Discover powerful TRIOS software that delivers exceptional user experience in a combined package for instrument control, data analysis and reporting for thermal analysis and rheology. New features such as automated calibration routines, multiple calibration sets, real-time test method editing, and inter-laboratory data and test method sharing provide unmatched flexibility, while one-click analysis and custom reporting raise productivity to new levels.

High Throughput DSC Autosampler

It’s hard to believe we could improve on the most reliable DSC autosampler on the market, but we did! The new linear autosampler was designed to be even more rugged and simpler to use than ever before.

Differential Scanning Calorimeters (DSC) measure temperatures and heat flows associated with thermal transitions in a material. Common usage includes investigation, selection, comparison and end-use performance evaluation of materials in research, quality control and production applications. Properties measured by TA Instruments’ DSC techniques include glass transitions, “cold” crystallization, phase changes, melting, crystallization, product stability, cure / cure kinetics, and oxidative stability.

Temperature Range: -180°C to 725°C

Detectable Information: Glass transitions, melting, crystallization, phase changes, heat capacity, cure kinetics, oxidative induction time

Thermomechanical Analyzers (TMA) measure changes in the dimensions of a sample as a function of time, temperature, and force in a controlled atmosphere.

Properties measured by TMA include the material’s coefficient of linear thermal expansion (CTE), shrinkage, softening, and glass transition temperatures. Modulated TMA (MTMA) can be used for deconvolution of the Total dimension change signal into Reversing and Non-Reversing dimension change signals for separating expansion from contraction, shrinkage, and stress relaxation.

Temperature Range: -150°C to 1000°C

Detectable Information: Coefficient of Thermal Expansion (CTE), sample expansion and contraction, softening points, glass transition temperatures, and delamination.

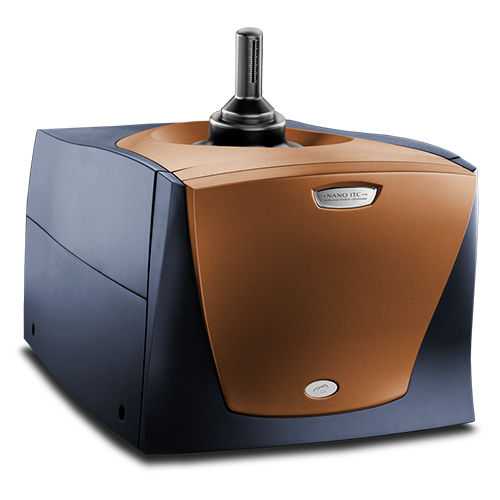

The Nano ITC Standard Volume and Nano ITC Low Volume isothermal titration calorimeters are designed to provide maximum sensitivity and flexibility for the study of biomolecular binding. Both instruments use solid state thermoelectric heating and cooling systems to precisely control temperature, and have the same flexible injection syringe assemblies for efficient and accurate delivery of titrant. The true isothermal power compensation design of the Nano ITC instruments provides the highest sensitivity and flexibility for an ultrasensitive ITC analyzing biological samples in-solution.

Temperature Range (Standard Volume): 2 °C to 80 °C

Discover powerful TRIOS software that delivers exceptional user experience in a combined package for instrument control, data analysis and reporting for thermal analysis and rheology. New features such as automated calibration routines, multiple calibration sets, real-time test method editing, and inter-laboratory data and test method sharing provide unmatched flexibility, while one-click analysis and custom reporting raise productivity to new levels.

Discover powerful TRIOS software that delivers exceptional user experience in a combined package for instrument control, data analysis and reporting for thermal analysis and rheology. New features such as automated calibration routines, multiple calibration sets, real-time test method editing, and inter-laboratory data and test method sharing provide unmatched flexibility, while one-click analysis and custom reporting raise productivity to new levels.

- Fusion Cell™ with patented technology provides unrivaled performance in baseline flatness, sensitivity, resolution, and reproducibility. Its superb technology enables detection of the weakest thermal transitions and the most accurate enthalpy and specific heat capacity measurements.

- Enhanced Tzero heat flow technology for the X3 guarantees temperature and enthalpy accuracy simultaneously on all three samples

- High-end performance with three sample calorimeters provide unmatched flexibility from replicate testing for statistical analysis to validation/verification against a control sample for the ultimate in certainty

- Modulated DSC® (MDSC®) for the most efficient separation of complex thermal events.

- One-Touch-Away™ User Interface enhances usability and access to data on the instrument.

- Reliable linear autosampler with 54 programmable tray positions for worry-free 24/7 operation, flexible programming of experiments, and automated calibration and verification routines.

- Widest range of refrigerated cooling options eliminates liquid nitrogen expense and ensures uninterrupted sub-ambient operation during extended autosampler routines.

- Tzero Press and pans for fast, simple, and reproducible sample preparation.

- Powerful software that delivers an exceptional user experience in a combined package for instrument control, data analysis, and reporting. Features such as automated calibration routines and real-time test method editing provide unmatched flexibility, while One-Click analysis and custom reporting raise productivity to new levels.

- Commitment to quality backed by the industry’s ONLY five-year cell and furnace warranty for peace of mind.

| Instrument Features | |

|---|---|

| Fusion Cell™ | X3 DSC |

| MDSC |  |

| Enhanced Tzero Heat Flow |  |

| User Replaceable Cell |  |

| 54-Position Autosampler |  |

| Dual Input Gas-Delivery Manifold |  |

| Color App-Style Touch Screen |  |

Included Included |

|

Revolutionary New Fusion Cell™

Revolutionary new Fusion Cell™ further improves the performance on which you’ve come to rely. Better sensitivity, resolution, repeatability and industry leading baseline performance, enable detection of the weakest thermal transitions and the most accurate enthalpy and specific heat capacity.

Powerful TRIOS Software

Revolutionary new Fusion Cell™ further improves the performance on which you’ve come to rely. Better sensitivity, resolution, repeatability and industry leading baseline performance, enable detection of the weakest thermal transitions and the most accurate enthalpy and specific heat capacity.

Modulated DSC®

Revolutionary new Fusion Cell™ further improves the performance on which you’ve come to rely. Better sensitivity, resolution, repeatability and industry leading baseline performance, enable detection of the weakest thermal transitions and the most accurate enthalpy and specific heat capacity.

RCS 120 Refrigerated Cooling System

Revolutionary new Fusion Cell™ further improves the performance on which you’ve come to rely. Better sensitivity, resolution, repeatability and industry leading baseline performance, enable detection of the weakest thermal transitions and the most accurate enthalpy and specific heat capacity.

High Throughput DSC Autosampler

Revolutionary new Fusion Cell™ further improves the performance on which you’ve come to rely. Better sensitivity, resolution, repeatability and industry leading baseline performance, enable detection of the weakest thermal transitions and the most accurate enthalpy and specific heat capacity.

New Microscope Accessory

Revolutionary new Fusion Cell™ further improves the performance on which you’ve come to rely. Better sensitivity, resolution, repeatability and industry leading baseline performance, enable detection of the weakest thermal transitions and the most accurate enthalpy and specific heat capacity.

Refrigerated Cooling Systems (RCS)

Take advantage of the convenient Refrigerated Cooling Systems (RCS) for unattended DSC and MDSC® operation over broad temperature ranges. The new RCS 120 provides enhanced safety and is the only liquid nitrogen-free system capable of conducting experiments down to -120°C.

RCS Features and Benefits:

- One-, Two-, or Three-stage refrigeration systems that achieve temperature ranges down to -40 °C, -90 °C or -120 °C

- Sealed system eliminates the need for liquid nitrogen cooling

- Enables cycling, MDSC®, controlled, and ballistic cooling experiments

- Safe, convenient, and continuous cooling operation for your laboratory needs

Refrigerated Cooling Systems (RCS)

Take advantage of the convenient Refrigerated Cooling Systems (RCS) for unattended DSC and MDSC® operation over broad temperature ranges. The new RCS 120 provides enhanced safety and is the only liquid nitrogen-free system capable of conducting experiments down to -120°C.

RCS Features and Benefits:

- One-, Two-, or Three-stage refrigeration systems that achieve temperature ranges down to -40 °C, -90 °C or -120 °C

- Sealed system eliminates the need for liquid nitrogen cooling

- Enables cycling, MDSC®, controlled, and ballistic cooling experiments

- Safe, convenient, and continuous cooling operation for your laboratory needs

Refrigerated Cooling Systems (RCS)

Take advantage of the convenient Refrigerated Cooling Systems (RCS) for unattended DSC and MDSC® operation over broad temperature ranges. The new RCS 120 provides enhanced safety and is the only liquid nitrogen-free system capable of conducting experiments down to -120°C.

RCS Features and Benefits:

- One-, Two-, or Three-stage refrigeration systems that achieve temperature ranges down to -40 °C, -90 °C or -120 °C

- Sealed system eliminates the need for liquid nitrogen cooling

- Enables cycling, MDSC®, controlled, and ballistic cooling experiments

- Safe, convenient, and continuous cooling operation for your laboratory needs

Refrigerated Cooling Systems (RCS)

Take advantage of the convenient Refrigerated Cooling Systems (RCS) for unattended DSC and MDSC® operation over broad temperature ranges. The new RCS 120 provides enhanced safety and is the only liquid nitrogen-free system capable of conducting experiments down to -120°C.

RCS Features and Benefits:

- One-, Two-, or Three-stage refrigeration systems that achieve temperature ranges down to -40 °C, -90 °C or -120 °C

- Sealed system eliminates the need for liquid nitrogen cooling

- Enables cycling, MDSC®, controlled, and ballistic cooling experiments

- Safe, convenient, and continuous cooling operation for your laboratory needs

Refrigerated Cooling Systems (RCS)

Take advantage of the convenient Refrigerated Cooling Systems (RCS) for unattended DSC and MDSC® operation over broad temperature ranges. The new RCS 120 provides enhanced safety and is the only liquid nitrogen-free system capable of conducting experiments down to -120°C.

RCS Features and Benefits:

- One-, Two-, or Three-stage refrigeration systems that achieve temperature ranges down to -40 °C, -90 °C or -120 °C

- Sealed system eliminates the need for liquid nitrogen cooling

- Enables cycling, MDSC®, controlled, and ballistic cooling experiments

- Safe, convenient, and continuous cooling operation for your laboratory needs

TRIOS Software

Discover powerful TRIOS software that delivers exceptional user experience in a combined package for instrument control, data analysis and reporting. New features such as automated calibration routines, multiple calibration sets, real-time test method editing, and inter-laboratory data and test method sharing provide unmatched flexibility, while one-click analysis and custom reporting raise productivity to new levels.

TRIOS Features & Benefits:

- Control multiple instruments with a single PC and software package

- Overlay and compare results across techniques including DSC, TGA, DMA, SDT and rheometers.

- Unlimited licensing and free lifetime software upgrades.

- One-Click analysis for increased productivity.

- Automated custom report generation including: experimental details, data plots and tables, control charts and analysis results.

- Convenient data export to plain-text, CSV, XML, Excel®, Word®, PowerPoint®, and image formats.

- Optional TRIOS Guardian with electronic signatures for audit trail and data integrity.• Modulated DSC® (MDSC®) for the most efficient separation of complex thermal events.

Ease-of-Use

TRIOS software makes calibration of the entire line of Differential Scanning Calorimeters simple. Users can easily generate multiple calibration data sets under varying experimental conditions (e.g. different heating rates or gas selections) and seamlessly switch between them to match the experimental conditions used for sample testing. Real-time signals and the progress of running experiments is readily available, with the added capability of modifying a running method on the fly. TRIOS software offers a level of flexibility that is unmatched in the industry.

Ease-of-Use

TRIOS software makes calibration of the entire line of Differential Scanning Calorimeters simple. Users can easily generate multiple calibration data sets under varying experimental conditions (e.g. different heating rates or gas selections) and seamlessly switch between them to match the experimental conditions used for sample testing. Real-time signals and the progress of running experiments is readily available, with the added capability of modifying a running method on the fly. TRIOS software offers a level of flexibility that is unmatched in the industry.

Ease-of-Use

TRIOS software makes calibration of the entire line of Differential Scanning Calorimeters simple. Users can easily generate multiple calibration data sets under varying experimental conditions (e.g. different heating rates or gas selections) and seamlessly switch between them to match the experimental conditions used for sample testing. Real-time signals and the progress of running experiments is readily available, with the added capability of modifying a running method on the fly. TRIOS software offers a level of flexibility that is unmatched in the industry.

Ease-of-Use

TRIOS software makes calibration of the entire line of Differential Scanning Calorimeters simple. Users can easily generate multiple calibration data sets under varying experimental conditions (e.g. different heating rates or gas selections) and seamlessly switch between them to match the experimental conditions used for sample testing. Real-time signals and the progress of running experiments is readily available, with the added capability of modifying a running method on the fly. TRIOS software offers a level of flexibility that is unmatched in the industry.

Ease-of-Use

TRIOS software makes calibration of the entire line of Differential Scanning Calorimeters simple. Users can easily generate multiple calibration data sets under varying experimental conditions (e.g. different heating rates or gas selections) and seamlessly switch between them to match the experimental conditions used for sample testing. Real-time signals and the progress of running experiments is readily available, with the added capability of modifying a running method on the fly. TRIOS software offers a level of flexibility that is unmatched in the industry.

TGA Part 1 - Theory & Instrumentation

Monday, June 22 at 1:00 pm EDT

This lecture-based course covers all our TGA instruments, but is mainly designed around the Discovery TGA 55, 550, & 5500 instruments. The course will cover:

- Theory of operation

- Instrumentation

- Experimental parameters

- Software operation

- Calibration

- Maintenance & Troubleshooting

- Applications

TGA Part 2 - Applications

Tuesday, June 23 at 1:00 pm EDT

This lecture-based course covers all our TGA instruments, but is mainly designed around the Discovery TGA 55, 550, & 5500 instruments. The course will cover:

- Theory of operation

- Instrumentation

- Experimental parameters

- Software operation

- Calibration

- Maintenance & Troubleshooting

- Applications

Request More Information

Trade in your Q Series DSC system and SAVE 40% on a NEW Discovery DSC

The world’s finest line of Differential Scanning Calorimeters

Trade in your Q Series DSC system and SAVE 40% on a NEW Discovery DSC

The world’s finest line of Differential Scanning Calorimeters

Technology

Discovery DSC

- New FusionCell™ with patented technology for unrivaled performance

- Exclusive Tzero® heat flow technology for ultimate DSC performance

- Unmatched baseline stability that requires no subtractions

- New linear 54-position autosampler

How the DSC and TMA together will benefit your lab:

Determine cure state and glass transitions of adhesives.

Measure the glass transition temperature and extent of cure of adhesives used to hold components in place on printed circuit boards. TMA is extremely sensitive to the multiple Tgs that may exist on a PCB. DSC can quickly capture any residual cure of epoxy components.

TGA Part 1 - Theory & Instrumentation

Monday, June 22 at 1:00 pm EDT

This lecture-based course covers all our TGA instruments, but is mainly designed around the Discovery TGA 55, 550, & 5500 instruments. The course will cover:

TGA Part 1 - Theory & Instrumentation

Monday, June 22 at 1:00 pm EDT

This lecture-based course covers all our TGA instruments, but is mainly designed around the Discovery TGA 55, 550, & 5500 instruments. The course will cover:

TGA Part 1 - Theory & Instrumentation

Monday, June 22 at 1:00 pm EDT

This lecture-based course covers all our TGA instruments, but is mainly designed around the Discovery TGA 55, 550, & 5500 instruments. The course will cover:

TGA Part 1 - Theory & Instrumentation

Monday, June 22 at 1:00 pm EDT

This lecture-based course covers all our TGA instruments, but is mainly designed around the Discovery TGA 55, 550, & 5500 instruments. The course will cover:

TGA Part 1 - Theory & Instrumentation

Monday, June 22 at 1:00 pm EDT

This lecture-based course covers all our TGA instruments, but is mainly designed around the Discovery TGA 55, 550, & 5500 instruments. The course will cover:

TGA Part 1 - Theory & Instrumentation

Monday, June 22 at 1:00 pm EDT

This lecture-based course covers all our TGA instruments, but is mainly designed around the Discovery TGA 55, 550, & 5500 instruments. The course will cover:

Related Application Notes:

Discovery DSC

- New FusionCell™ with patented technology for unrivaled baseline flatness, sensitivity, and resolution

- Exclusive Tzero® heat flow technology for ultimate DSC performance

- Unmatched baseline stability that requires no subtractions

- New linear 54-position autosampler

Discovery SDT

- Simultaneous DSC/TGA

- Advanced modes for heat capacity, kinetic studies, and better resolution

- Horizontal dual-beam design for superior heat flow and weight measurements

- New 30-position autosampler with programmable tray positions

Discovery TGA

- New ultrasensitive proprietary Tru-Mass™ thermobalance

- The most accurate real-time data

- Superior atmosphere control to meet the most demanding applications

- Rugged & reliable automation

Discovery DSC

- New FusionCell™ with patented technology for unrivaled baseline flatness, sensitivity, and resolution

- Exclusive Tzero® heat flow technology for ultimate DSC performance

- Unmatched baseline stability that requires no subtractions

- New linear 54-position autosampler

Discovery DSC

- New FusionCell™ with patented technology for unrivaled baseline flatness, sensitivity, and resolution

- Exclusive Tzero® heat flow technology for ultimate DSC performance

- Unmatched baseline stability that requires no subtractions

- New linear 54-position autosampler

Discovery DSC

- New FusionCell™ with patented technology for unrivaled baseline flatness, sensitivity, and resolution

- Exclusive Tzero® heat flow technology for ultimate DSC performance

- Unmatched baseline stability that requires no subtractions

- New linear 54-position autosampler

Learn how the instrument package below will optimize your product development by providing crucial information on material compatibility, cure states, glass transitions, and more.