MEDICAL DEVICE LAB PACKAGE

Accelerate your device durability tests by combining multiple techniques

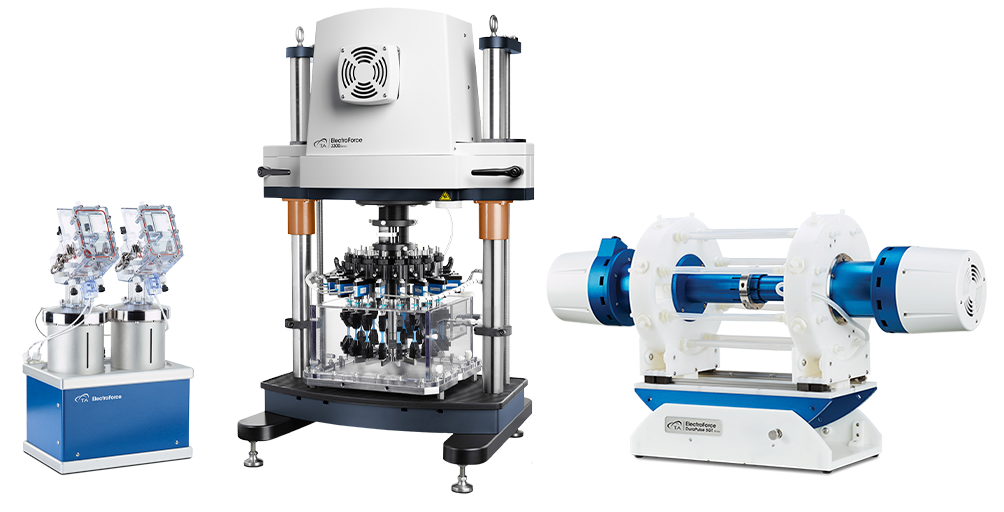

Accelerate fatigue to fracture or test to success tests of materials or device subcomponents using MSF technology

Rapidly push many specimens to fatigue failure to establish reliable fatigue limits (often per ASTM F3211) using the MSF16 Multi-Specimen Fatigue instrument. These tests can enable rapid device optimization or faster regulatory approval by directly pulling or pushing your material or devices to failure at frequencies up to 100Hz. Or, use its high sample count and speed capability to complete your 400 or 600 million cycle test to success programs as fast as possible, accelerating your time to market.

Final device testing is done better and quicker with DuraPulse.

ElectroForce DuraPulse instruments enable you to fatigue test your final cardiovascular devices with more consistent loading and higher frequencies giving you results you can trust in the shortest time possible. Whether it’s the modular DuraPulse SGT for pulsatile durability of virtually any sized device per ASTM F2477 or ISO 25539 or the DuraPulse HVT for durability testing of surgical and transcatheter heart valves per ISO 5840, DuraPulse will get it done with speed and consistency.

The capable combination of ElectroForce MSF and DuraPulse instruments will provide the power, speed and repeatability you need to deliver your fatigue results quickly and therefore accelerate your product development and regulatory approvals.

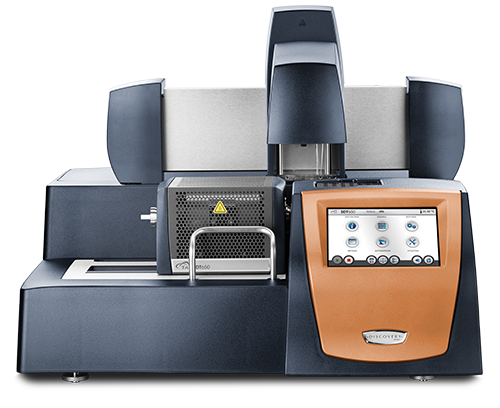

TA Instrument’s Multi-Specimen Fatigue Instruments are designed to accelerate fatigue studies for a variety of materials, subcomponents and complete devices. With the capability of simultaneously testing up to 16 specimens at up to 100 Hz, users can generate S/N curves faster and with higher statistical confidence levels than ever before. In this system, proven and refined technologies come together to quickly and confidently deliver results.

Key Features

- Simultaneous axial fatigue of 16 specimens

- Unparalleled durability and dynamic performance with the patented ElectroForce linear motor technology

- Accelerated testing frequencies up to 100 Hz with unparalleled displacement amplitudes

- Nanometer resolution and 5 micron accuracy displacement sensor

- Independent force measurement for each specimen for real-time independent specimen failure detection

- Individual precision adjustment and locking mechanisms for each specimen

- Auto-fill fluid bath for convenience and stable temperature control from ambient to 45 °C

- Integrated overtravel stop for reliable specimen protection

- Complete visibility of all 16 specimen for easy optical measurements

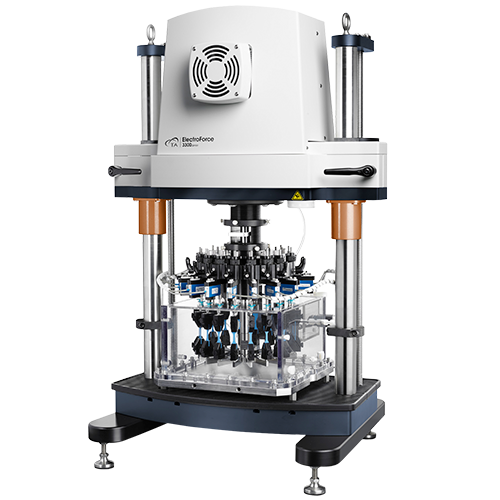

The NEW DuraPulse™ Stent/Graft test (SGT) instrument extends the performance and reliability that ElectroForce SGTs have become known for over the past 20 years. Still utilizing proprietary high-bandwidth, low-distortion ElectroForce actuator technology to provide best-in-class performance, the DuraPulse SGT incorporates a modular manifold design that allows the user to easily change out manifold and tube sets to optimize sample throughput for various stented device sizes. An enhanced software user interface is easier to use and includes inner diameter (ID) and outer diameter (OD) radial strain calculations, improved strain control modes, and simplified data acquisition.

Key Features

- Achieve highest strain and frequency combinations with closed-loop, symmetric dual-sided pulse

- Single test instrument can be optimized for device geometry and sample number with interchangeable manifold sets – 12, 8, 6, and 4 (bifurcated) mock vessel options

- Accommodates wide range of device diameters – 2 mm to 50 mm

- Conveniently measure tube strain across all tubes with optical micrometer positioning slide and 360° manifold rotation, and a tube scanning function that holds command levels and allows the laser to be repositioned during testing

- Select from 3 ID/OD Strain Calculation modes including Zero Strain or Zero Stress

- Conditions (as defined by ISO 25539-2)

- Automate test pressure control with optional Pressure Control Accessory (PCA)

- Clearly identify system operation state with System Status Indicator (SSI) lights

- Instrument reliability for years of use supported by industry leading 10 year actuator warranty

- Meets or exceeds international testing standards such as ISO 25539-2 and ASTM F2477

Using proprietary ElectroForce controls and linear motor technology, the DuraPulse™ Heart Valve Test (HVT) instrument achieves smooth waveform fidelity and precise control for accelerated heart valve durability testing. Automatic PeakIQ™ control algorithms and independent test chambers ensure that established test conditions are maintained on each valve throughout the test. The DuraPulse HVT instrument provides testing to the ISO 5840 standard for heart valve durability assessment.

Key Features

- High frequency operation

- PeakIQ™ waveform control to prevent high pressure spikes on valve closing.

- Automatic controls (closed-loop feedback) to maintain test conditions throughout test

- Modular, independent control of each heart valve station

- Simplicity in transfer of heart valve device from durability test instrument to pulse duplicator

- 2, 4, or 6-station unit

- Reliable – 10 year warranty on linear motors

Technology

How the MSF-16 and DuraPulse SGT or HVT will together benefit your lab:

Proven reliability and speed for your demanding durability test programs

ElectroForce instruments continue to deliver the fastest results and demonstrate superior reliability with powerful frictionless motors, non-contact sensors and control systems that are built for your most demanding fatigue tests, often running without interruption or down-time for months.