POLYMER LAB PACKAGES

Advance your polymer lab by combining multiple techniques

Learn how the instrument packages below will help you characterize your polymeric materials at every stage of manufacture.

Learn how the instrument packages below will help you characterize your polymeric materials at every stage of manufacture.

Gain insight into curing times to optimize processing conditions, saving valuable time and money.

Process optimization – oven temperature, molding times, and more. Determine the presence of residual cure and Tg position.

Industry leading reproducibility of results that provide an accurate measure of composite composition.

With TGA quantify filler content or monitor the presence of volatiles.

Differential Scanning Calorimeters (DSC) measure temperatures and heat flows associated with thermal transitions in a material. Common usage includes investigation, selection, comparison and end-use performance evaluation of materials in research, quality control and production applications. Properties measured by TA Instruments’ DSC techniques include glass transitions, “cold” crystallization, phase changes, melting, crystallization, product stability, cure / cure kinetics, and oxidative stability.

Temperature Range: -180°C to 725°C

Detectable Information: Glass transitions, melting, crystallization, phase changes, heat capacity, cure kinetics, oxidative induction time

A rotational rheometer is used to measure viscosity (eta) and viscoelasticity (G’, G” and Tan delta) properties of a material. Rheometers can handle all kinds of samples from low viscosity liquids (e.g. water or solvents), semi-solid or soft gels, to high stiffness and high modulus solids. A rotational rheometer can perform flow measurements to test the viscosity of a liquid as a function of time, temperature shear rate or shear stress. Flow tests can also be used to measure the yield stress and thixotropic properties of a structured fluids. The rheometer can also perform dynamic oscillatory measurements to measure the viscoelastic properties of a semi-solid or solid sample. Typical oscillation tests are used to verify the linear viscoelastic region; monitor thermoset curing or sample stability; quantify differences in different formulations; measure polymer melts to compare differences in their molecular weight and molecular weight distribution; measure sample modulus and elasticity change as a function of time and temperature; measure glass transition (Tg) and sub-ambient transitions of polymers or polymer blends. In addition, a rotational rheometer can also perform transient type of measurements to study creep-recovery and stress relaxation.

Temperature Range: -150°C to 600°C

Detectable Information: viscosity, yield stress, thixotropy, curing, modulus (G’, G” G*), damping factor (tan delta), glass transitions, sub-ambient transitions, stress relaxation, creep-recovery

Thermogravimetric Analyzers measures temperatures and weight changes associated transitions in a material. Common usage includes decomposition, volatilization, residue, material composition analysis, decomposition kinetics, thermal and oxidative stabilities.

Temperature Range: 30°C to 1200°C

Detectable Information: weight change temperature, weight change amount, decomposition kinetics, residue.

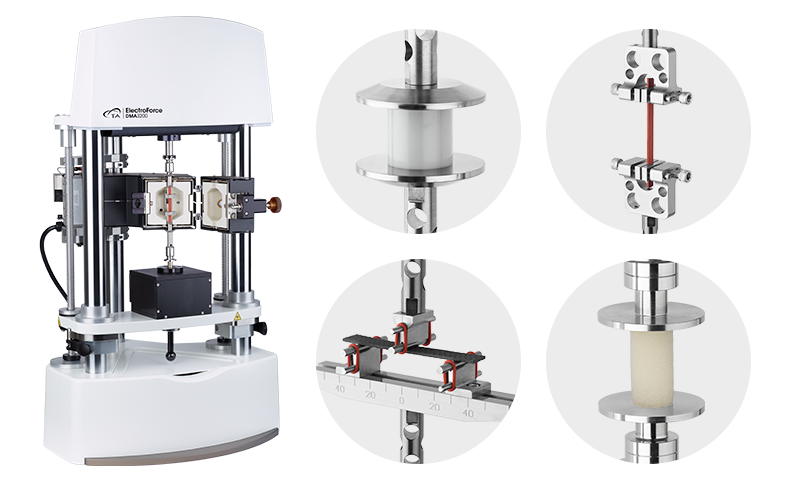

The DMA 3200 features patented ElectroForce linear motor technology enabling a single instrument to deliver unequalled performance and data accuracy. This unique motor technology combines powerful rare-earth magnets with a frictionless flexural suspension for the most precise force and displacement control over a wide range of frequencies and amplitudes. The DMA 3200 motor delivers a force output of up to 500 N and controlled displacements ranging from 1 micron to 13 mm. Testing can be conducted in both static and dynamic modes.

In addition, the frictionless, moving-magnet design eliminates failure points that exist in other motor designs, such as moving wires and bearing degradation. This ensures the most durable and reliable performance; proven over billions of cycles through decades of maintenance-free use in ElectroForce fatigue test instruments. It is the only motor in the industry backed by a ten-year warranty.

This efficient, quiet, and lubrication-free motor technology allows the DMA 3200 to be used virtually anywhere; from lab to production floor, or from the cleanroom to office space.

Key Features

- Patented, linear motor and high-resolution displacement sensor provides unmatched control over the widest ranges of force, displacement, and frequency, for superior data accuracy

- Ultra-durable, frictionless motor, backed by industry’s only ten-year warranty, provides maintenance- and worry-free operation

- High force of 500 N enables testing of larger samples or final parts under real-world conditions, by achieving higher loading levels in both DMA and fatigue analysis

- Forced Convection Oven (FCO) provides superior control and responsiveness over a temperature range of -150°C to 600°C for the highest degree of accuracy and flexibility in experiment thermal profiles

- Large Sample Oven (LSO), with a temperature range of -150°C to 315°C, offers spacious interior dimensions to accommodate testing of large samples or components

- Air Chiller Systems (ACS) offer unique gas flow cooling for sub-ambient testing without the use of liquid nitrogen, eliminating potential laboratory hazards while providing an incredible return on investment

- Broad range of fixtures accommodate a wide range of sample sizes and geometries adding to testing versatility

- Extremely rigid test frame and air bearings ensure the most accurate results on samples of very high stiffness

- Multi-color status lights provide clear and visible indication of instrument and test status

- WinTest® and TRIOS Software packages provide powerful and easy-to-use instrument control and data analysis for the ultimate flexibility in experimental design

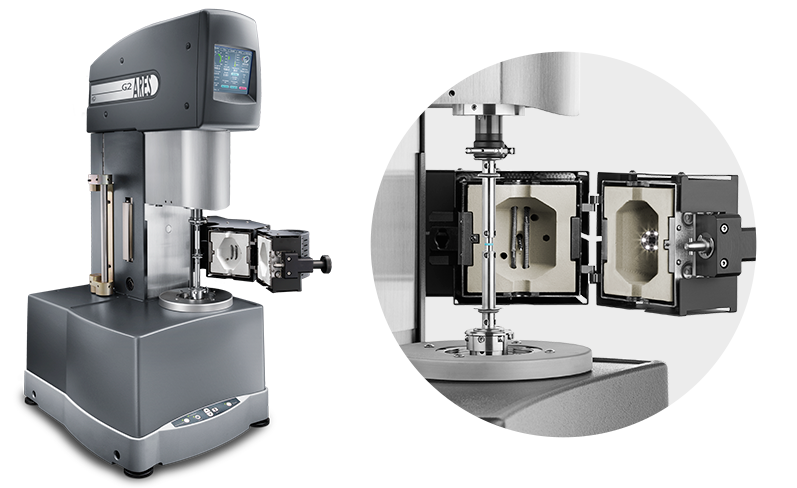

The ARES-G2 is the most advanced rotational rheometer for research and material development. It remains the only commercially available rheometer with a dedicated actuator for deformation control, Torque Rebalance Transducer (TRT), and Force Rebalance Transducer (FRT) for independent shear stress and normal stress measurements. It is recognized by the rheological community as the industry standard to which all other rheometer measurements are compared for accuracy.

Key Features

- Unrivaled data accuracy

- Unmatched strain and new stress control

- Fully integrated fast data sampling

- Separate electronics

- New Smart Swap™ environmental systems

- Patented Active Temperature Control

- Advanced accessories

- TRIOS Software providing extreme testing flexibility

- Large Amplitude Oscillatory Shear (LAOS) and Fourier Transform (FT) Rheology

- Analysis Software package

- NEW Orthogonal Superposition (OSP) and 2 Dimensional Small Amplitude Oscillatory

- Shear (2D-SAOS) techniques

- NEW DMA mode for measurements of solids in bending, tension and compression

High-Force DMA and fatigue capability aimed at characterizing your larger and stronger materials or components

The DMA 3200 combines decades of cutting-edge fatigue and world-leading Dynamic Mechanical Analysis technologies into a unique and highly versatile testing platform. With 500 Newton force capacity and a variety of ovens and fixtures for a wide range of sample sizes including components, it broadens the range of what you can evaluate using DMA methods and has the power and speed for the demands of fatigue testing.

Reliability in measurements and durability

You can count on the DMA 3200 for the precision measurements of force, displacement and temperature required for DMA results as well as the mechanical robustness and durability required for many-million cycle fatigue tests. With this combination you will quickly get the results you need and minimize downtime in your laboratory.

Combine the ARES-G2 rheometer with its Forced Convection Oven accessory

How the ARES-G2 will benefit your lab:

Directly link molecular architecture with processing and product performance properties

Polymer architecture, molecular weight, and molecular weight distribution drive processing behavior and product performance. Rheology data acts as a fingerprint of polymer systems through viscoelastic characterization and melt viscosity measurements. Gain clarity on architecture to confirm polymer synthesis and predict polymer processing and product performance with the ARES-G2, for research and development or quality control purposes.

Combine the techniques of the Discovery DSC and Discovery TGA

How the DSC and TGA together will benefit your lab:

Easily quantify the effects of formulation changes on cure reaction kinetics or curing temperature.

Capture cure temperature reaction kinetics from the DSC for complete resin characterization. Tailor reaction kinetics through changes in resin formulation.

Combine the techniques of the Discovery DSC and HR Rheometer

How the DSC and HR together will benefit your lab:

Confidently characterize polymer samples from synthesis to final product

The superior measurement sensitivity of the HR 30 and flat baseline of the Discovery DSC deliver measurement quality you can depend on. Viscoelastic measurements can be used to gain insight into the molecular weight and molecular weight distribution, while DSC can be used to examine the impact of thermal history and formulation changes on the polymer properties and crystallization behavior. Whether you are gaining insight for research and development or for quality control purposes, TA believes you should be confident in your measurements.

Combine the High Force DMA 3200 and its multiple accessories to get the most from your lab

How the DMA 3200 will benefit your lab:

Adaptable to meet your needs with a range of accessories

The DMA 3200 has a wide range of accessories you can choose from and combine to deliver the results you need. With two ovens, three cooling accessories and a wide range of grips you can create the perfect configuration for your characterization needs.